Adhesive Bonding & Foaming.

Adhesive Bonding AND Foaming

Bonding is the joining technology of the 21st century! For many years we have been working with various adhesives in accordance with DIN 2304 and have achieved outstanding results in stability, durability and lightness in more and more areas and with more and more materials. Structural bonding, for example, enables increased inherent strength and high durability of the joints. Our trained adhesive engineers, adhesive specialists and adhesive technicians are regularly trained at the Fraunhofer Institute and create with great enthusiasm innovative adhesive-technical joints that stand for one thing above all else: safety!

Due to the large-area joint through bonding, an even distribution of stress is created under load. The surfaces of the joined parts remain completely intact, as they are not locally weakened by drilling, as is the case with screws or rivets.

At the same time, a higher vibration damping is achieved than with a welded or riveted connection. Last but not least, a noticeable weight reduction can be achieved, so that the bonded components can contribute to fuel reduction and increase the payload, especially in the transport sector.

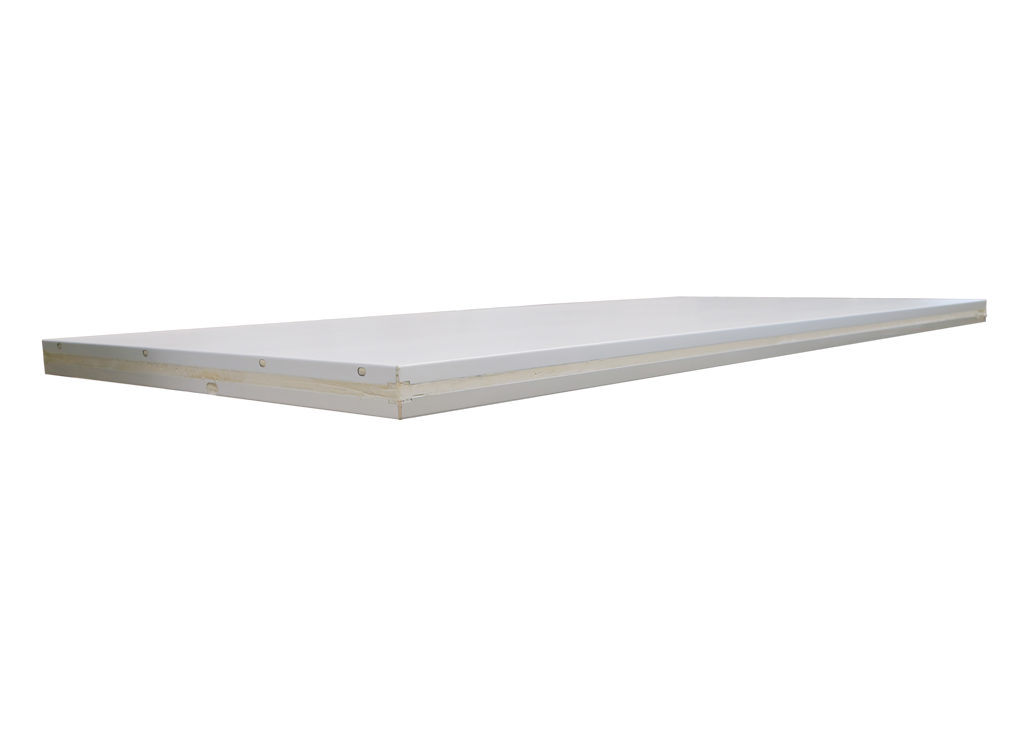

In foaming, hollow or filling spaces are specifically filled, whereby the foam forms a firm adhesive bond with the adjacent components. With foaming, we produce components with special properties. Examples are foamed panels or doors, which have been produced by XBond for years in a very high variety and variance. In particular, the integration of further additional functions by inserting reinforcements, cable ducts, connection points, etc. creates a wide range of possible applications for components produced by foaming.

1 Wide range of applications

With the right combination of pretreatment, joining parts as well as adhesive and/or foam, an optimised result can be achieved for a wide range of applications and uses.

2 Know How

Skilled personnel trained as adhesives engineers, adhesives specialists and adhesives practitioners

3 Lightweight construction

Due to the flat connection in both bonded and foamed components, lightweight structures with a lower weight and increased economic efficiency are created.

4 Insulating effect

By using foamed components, a high insulating effect is achieved for different applications.

5 Surface

The strength of the parts to be joined is completely retained, as there is no local weakening through drilling, as is the case with screws or rivets.

6 Large area joint

A large-surface joint ensures strong hold and even strain.

7 Elasticity

The elasticity of the adhesive in a bonded joint enables increased vibration damping compared to a pure welded or riveted joint.

39 years

experience in adhesive bonding

more than 10.000

bonded / foamed assemblies p.a.

DIN 2304

Safety standard

Leistungen

Kontakt

XBond GmbH & Co.KG

Im Garbrock 29

48683 Ahaus-Ottenstein,

Deutschland

Telefon: 02561 / 9831-0

Telefax: 02561 / 9831-31

Schreiben Sie uns